| Technical Data: | SKM 10 | SKM 16 |

| Shank diameter (mm): | 2,0-10,0 | 4,0-14 (16) |

| Max. diameter to pass feed rails (mm): | 12 | 16 |

| Shaft length (mm): | 10-180 | 10-220 |

| Max. spindle traverse (mm): | 20,0 | 20,0 |

| Spindle speed variable (min.–1): | 12.000 | 10.000 |

| Output (max. pcs/min.*): | 300 | 250 |

| Machine weight (approx. kg): | 3.200 | 3.200 |

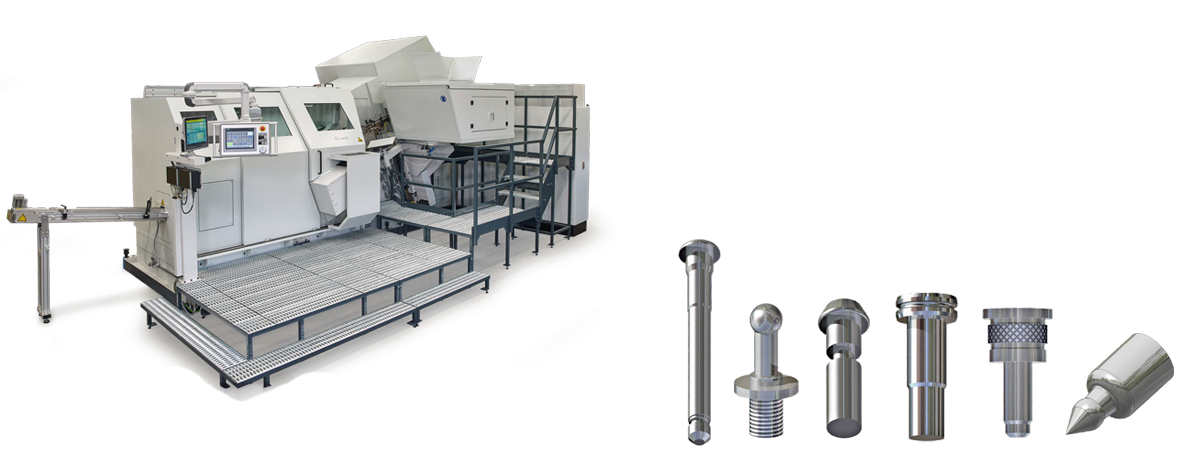

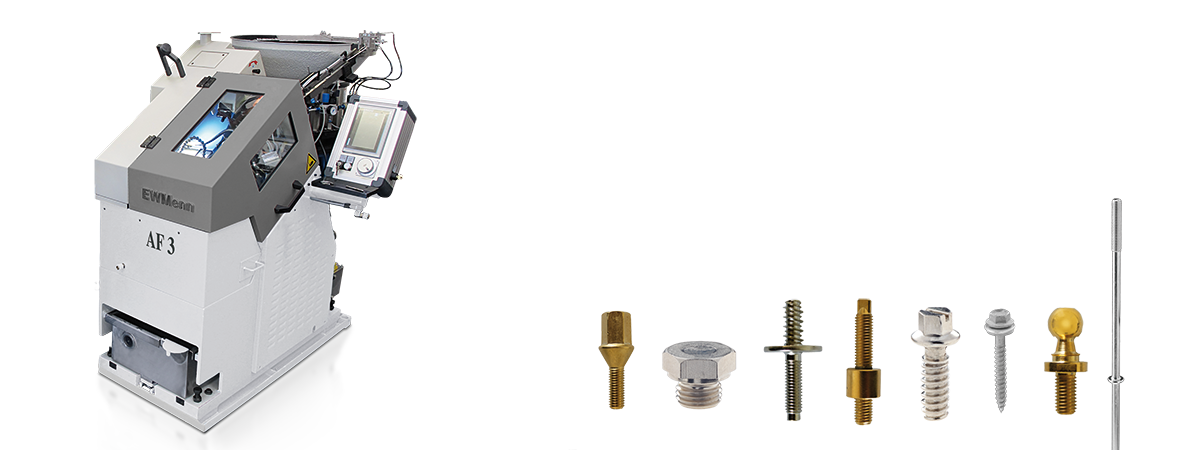

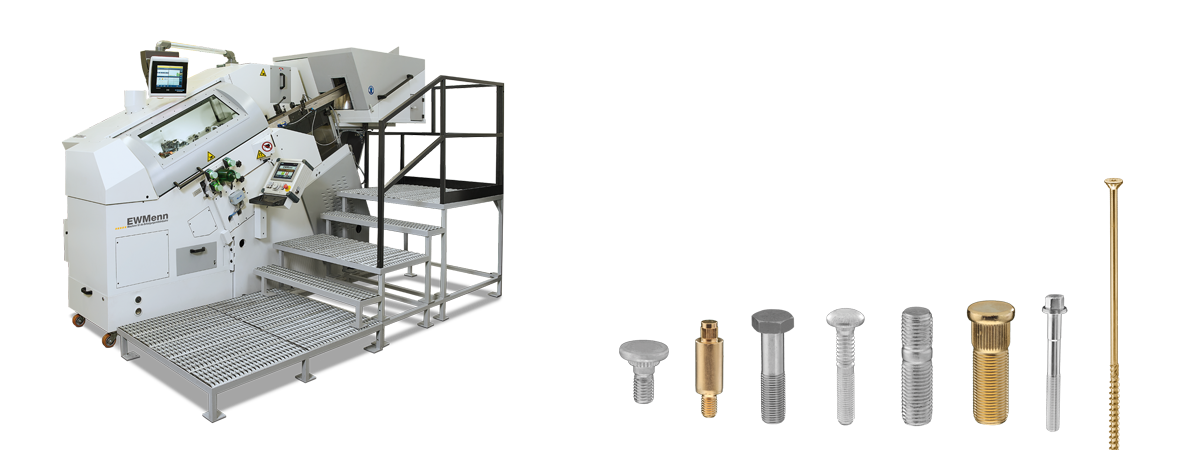

Roll forming machines

AF 2, AF 3

High performance thread- and profile rolling machines with flat dies in horizontal format

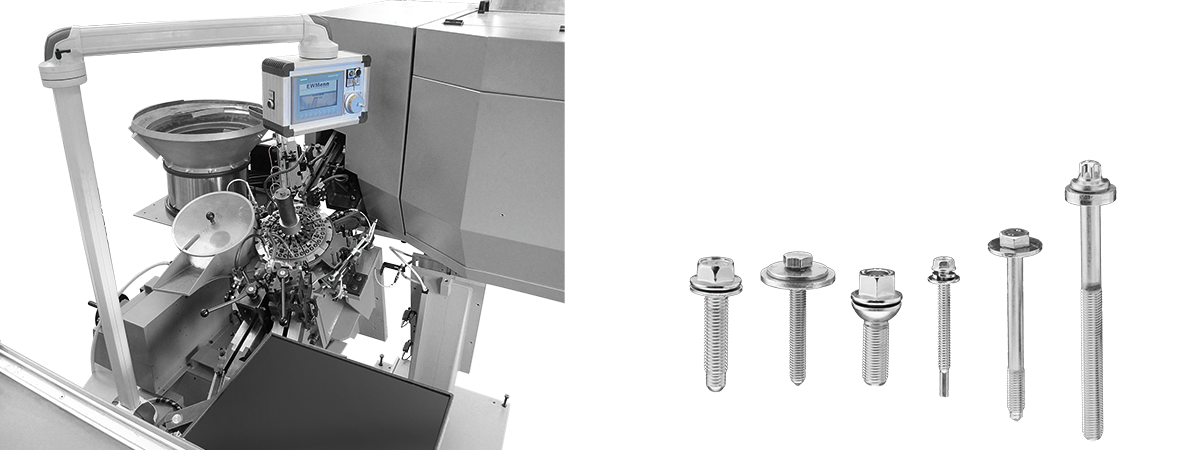

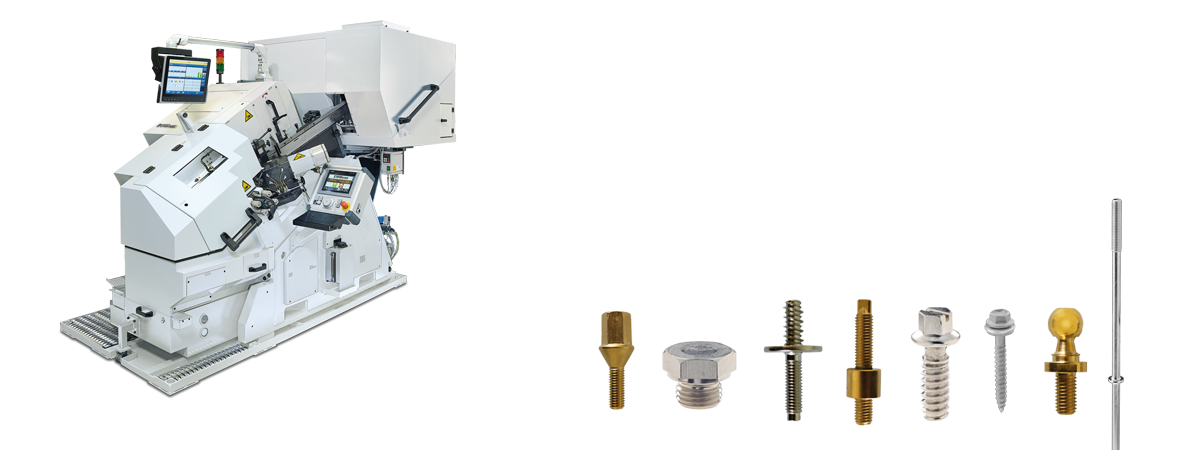

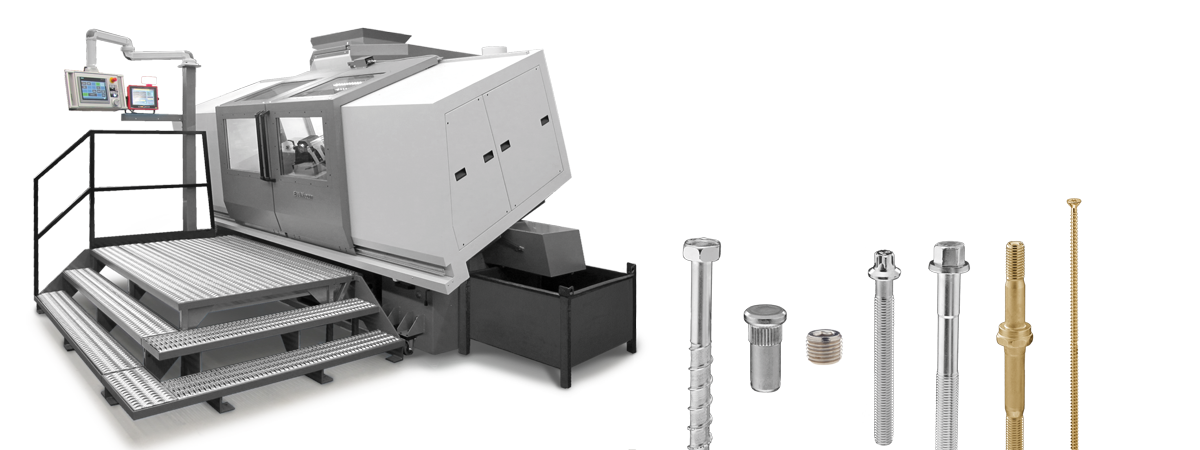

Roll forming machines

AF 51, AF 61

High performance thread- and profile rolling machines with flat dies in horizontal format

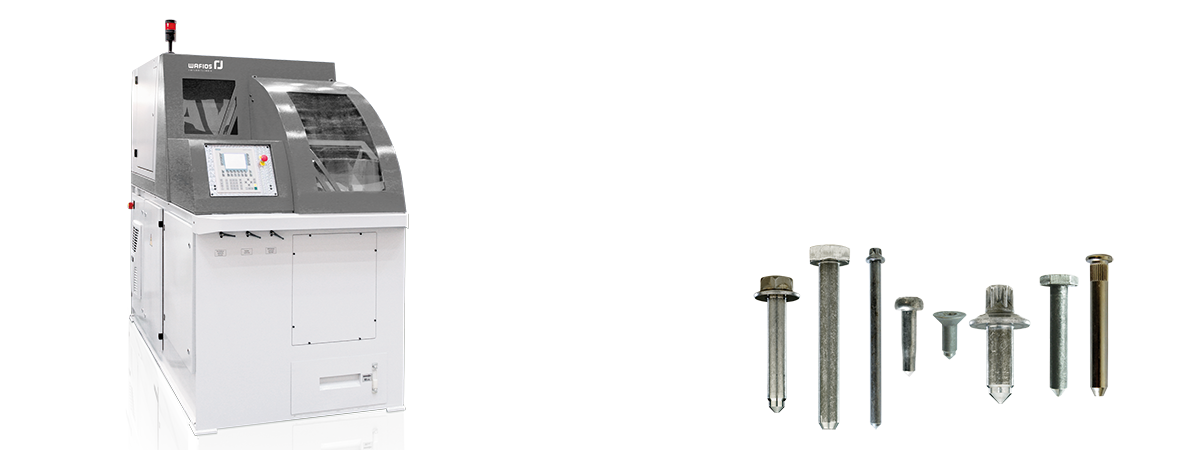

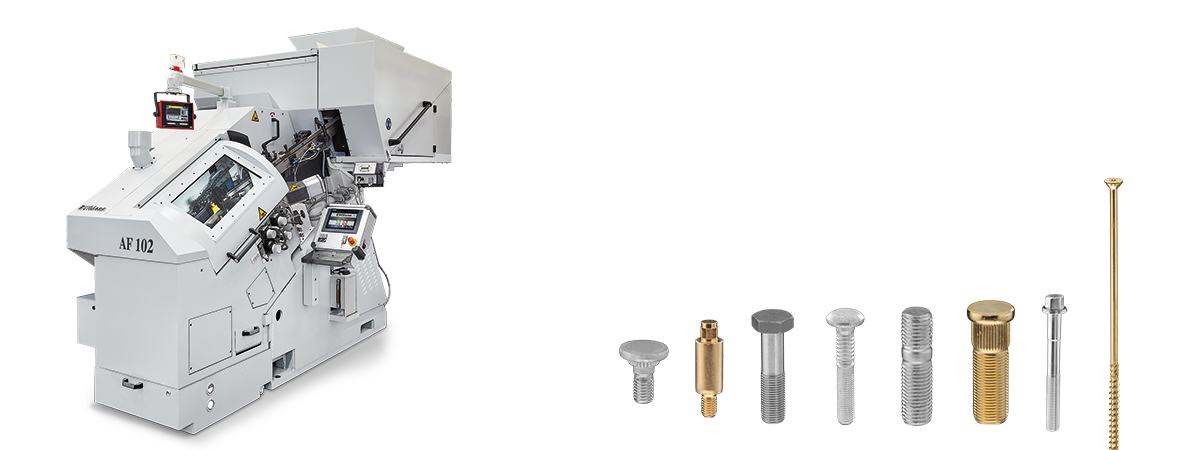

Roll forming machines

AF 82, AF 102

High performance thread- and profile rolling machines with flat dies

Roll forming machines

AF 121, AF 141

High performance thread- and profile rolling machines with flat dies

Roll forming machines

GW 121-H, GW 141-H

High performance thread- and profile rolling machines with flat dies in horizontel format

Roll forming machines

GW 141-HX, GW 141-HXL

High performance thread- and profile rolling machines with flat dies in horizontel format